We stand for the highest precision and a reliable partnership

EPMODEX IMAGE BROCHURE

DownloadOUR SERVICES

Product Design & Development

Product Authorization

READ MORE

System Realization

READ MORE

YOUR RELIABLE PARTNER

epmodex is specialized in the development and certification of systems and advanced assemblies with highest requirements on reliability and safety of the products.

Whenever you demand excellent behaviour from your products you can only rely on the best! With us as your partner you profit from fast time-to-market deliveries, the highest precision, low compliance risks, optimal solutions and a reliable partnership. Even for ambitious and complex challenges, we deliver with highly proficient specialists, smart solutions and high-tech manufacturing equipment.

As a one-stop shop!

Thanks to our many years of experience in medical products and other demanding industries our products meet the highest tolerance levels and perform even in the harshest of environments where other parts fail. To provide our clients with the best solutions, we work hand-in-hand with our carefully selected production partners in order to meet the standards of the European and American markets.

It is our mission to continue the development of technologies and processes. By our strong collaboration with the industry and science we use the most up-to-date technical practices and standards. Our clients know that we fully adhere to their industrial standards and that we stand for personalized assistance, fast response times, on time delivery, high flexibility and by every means the most economical solution.

OUR SPECIALISTS

You are in good hands with our specialists with many years of experience

Martin Epper, Dipl. Ing. FH

Managing Director / Owner

As a mechanical engineer with specialization in biomechanics and production techniques I support companies in the development, certification and market introduction of medical devices. When I founded epmodex in 2009 my motivation was to help companies to expedite time-to-market project lead times while keeping the safety standards of their new products very high. Today, I'm leading projects while keeping product requirements, safety aspects and deadlines in a holistic approach in mind.

Markus Angst, M Sc ETH Zurich

Senior Quality & Regulatory Consultant

I have 30 years of experience in medical devices, covering sterile devices and implants, biomechanics, quality assurance and regulatory affairs. I've been giving support to the development of various medical devices for epmodex’s small and large clients for the main markets.

I'm involved in several tasks at epmodex, such as regulatory/quality, development support, road-mapping as well as verification/validation activities.

Isa Epper

Customer Service / Member of the Board

As a professional in organizational topics I’m in charge of epmodex’s accounting, marketing activities, customer relations, logistics and support in quality assurance activities. I like the variety and daily challenges of my job and using my skills I do support the team where help is needed.

Petros Nianias

Product Development

My special skills are to find the best geometry and shape to fulfill all specific product requirements. Always considering the best risk-benefit approach. Further, it’s my passion to transfer a product prototype into a ready-for-serie product to allow a smooth production transfer. Using my expertise, I can optimize the product assemblies to any requested quantity and quality.

Christian Dillier

Sales

My passion is to bring new innovative products to the market. Since my apprenticeship I have been working in industry- and medical technology. In my former profession as a polymechanic, I’ve had the opportunity to get to know many different industries and manufacturing processes during my career. During my training as a technician for business processes, I learned to apply methods in practice to design processes efficiently. Today, it’s a great pleasure for me to apply the collected know-how in sales every day.

Christoph Teichler, Dipl. Ing. ETH

Product Development and Consulting

Being a mechanical engineer by training, I have worked in medical device companies in Europe and Asia for the last 15 years. I started in product development and branched out into product marketing and sales. With my several years of experience I can provide guidance on product registration and marketing strategy with a pragmatic and industrious approach.

PRODUCT DESIGN & DEVELOPMENT

Straight forward development at your finger tips

epmodex is your design- and development specialist. Our wealth of experience in a diverse array of demanding industry applications enables us to integrate a wide range of technologies quickly, competently and economically. Using a combination of creative and systematic methods, we offer you tremendous innovation along with optimum process reliability and very high standards of documentation.

Our services:

- Startup coaching

- Patent research and -Application

- Product Development / Quality Engineering

- Risk management according to ISO- 14971

- Regulatory strategy & consulting

- Clinical evaluations

- EU MDR & US FDA certifications and approvals

- Installation and development of a quality management system according to ISO-13485

- Road mapping

- Verification, validation activities

- Industrialization, design transfer

- Product labeling & packaging / UDI

- Life cycle management

- Project management

- Notified body search, application

- Product monitoring, Post Market Clinical Follow UP (PMCF)

- Supplier Quality Assurance

- Management Reviews

We provide expertise in the following medical markets:

- Dental

- Traumatology

- Orthopaedics

- Spine

- Surgical innovative instruments

- Combination products

Medical device regulation (MDR)

Since May 26th 2021, the Medical Device Regulation is fully applicable. Hence, all processes related to design, industrialization, manufacturing, marketing and market surveillance have to be aligned with the quality management system which must be compatible with ISO 13485:2016 and/or USA QSR.

We help you to get there - Due to our top-level expertise and a wealth of experience we advise and support our global customers in updating and correcting their technical documentation. With this service, we ensure to successfully accelerate procedures along the entire life cycle of medical devices to keep the products safe. Our clients know that we fully adhere to their industrial standards and that we stand for personal assistance, fast response times, on-time delivery and the highest level of flexibility.

Keen to see how you get your products MDR compliant in 7 steps?

MDR - Outsource and focus on your strengths

The new Medical Device Regulation is now reality and a major and significant challenge for most medical technology manufacturers. As if the stricter regulations were not difficult enough, they come at a time when manufacturers are struggling to defend their position in a highly competitive market and are being forced to shorter innovation cycles.

If you want to see how you convert the challenges into a unique chance, download our whitepaper!

EPMODEX AS YOUR NEW SWISS AUTHORIZED REPRESENTATIVE (SWISS AR)

With the termination of the negotiations of the Federal Council with the European Union (EU) on the Institutional Agreement (InstA) on May 26, 2021, the temporary Medical Device Ordinance (MedDO) has been automatically installed. With respect to a transition period (depending device classification) all Non-Swiss Manufacturers will have to comply with specific Swiss requirements per temporary Medical Device Ordinance soon. This includes the appointment of a Swiss AR for all medical devices imported into Switzerland.

The appointment of a Swiss AR cannot happen overnight. Even once the manufacturer has identified the most convenient entity in Switzerland, the designation process entails, at a minimum:

- Contract negotiation.

- Setting up internal procedures in the manufacturer’s Quality Management System to describe the communication processes.

- Agreement on the logistics to ensure the most suitable means of sharing information and documents (including the medical device’s Technical Documentation).

- Implementing the Swiss Authorised Representative’s particulars on the device labelling, as required.

It is therefore recommended that manufacturers based outside of Switzerland or currently represented by a European Authorised Representative not based in Switzerland start the mandate installation immediately.

epmodex as your new Swiss AR will help you to continue your growth in selling your products in Switzerland even under these circumstances. Use our wealth of experience and challenge our top-level service!

Keen to learn more?

Frequently asked questions (FAQ)

Swiss Authorised Representative

Product Registration

-High-risk devices (Class III, IIb implantable and AIMD): 31 December 2021

-Moderate-risk devices (non-implantable Class IIb, Class IIa): 31 March 2022

-Low-risk devices (Class I): 31 July 2022

-Systems and procedure packs: 31 July 2022

All other foreign manufacturers are required to appoint a Swiss authorised representative with effect from 26 May 2021.

Registration of Economic Operators

CHRN Swiss Registration Number

Obligations for MDD/ AIMDD devices

Labeling of Legacy Devices (MDD)

Labeling of MDR Devices

-Until 31.12.2021 Class III, implantable devices Class IIb and active implantable medical devices

-Until 31.03.2022 non-implantable devices class IIb and devices Class IIa

-Until 31.07.2022 Class I, systems and treatment units

Validity of Notified bodies in Europe

Treatment of other European Directives

SYSTEM REALIZATION

Systems Engineering is the key when merging different technologies together. Or further, on security-relevant missions that cannot be examined on the basis of a prototype run. Systems Engineering is an established standard- not only in the medical device industry. It is firmly anchored in projects and in the organization. Without the holistic and systematic approach and the consistent use of methods and processes of systems engineering there's no guarantee for a successful project implementation as "first time right".

We ensure that the result meets the requirements, and in the first attempt and at the right time. The methodology is established where complex interrelationships prevail or where safety-critical aspects have an impact and human lives are in danger. Nothing is left to chance and may go wrong with the introduction. Therefore, Systems Engineering has been used in our projects for years.

We offer precisely interlinked and modular services for complex products associated with very small error tolerances, high standards of documentation and very detailed change management– all in accordance with ISO 9001 and ISO 13485.Thanks to our team of qualified experts, our clients benefit from technical expertise in all areas of product realization and product life cycle management. We can guarantee quality, short lead times and punctual delivery thanks to our comprehensive expertise and end-to-end processes – as a one-stop shop.

PROJECTS

PLASS RESCUE OCCLUDER

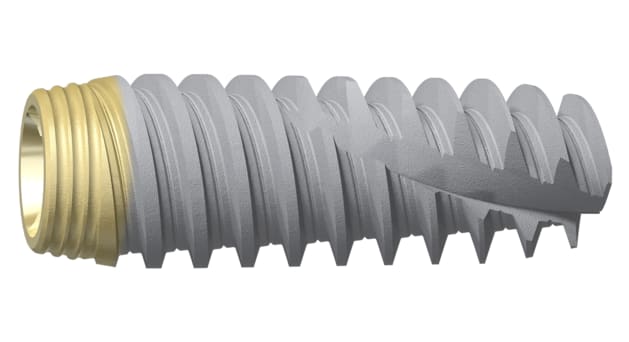

NOBEL BIOCARE

epmodex supported Nobel Biocare in a remediation program of their technical- and risk management file documentation for MDR compliance. We further supported them as an advisor in design risk management aspects for a compliant execution of their development projects in close cooperation with research, product development- and operations divisions.

QUALITY IS OUR HIGHEST PRIORITY

Accuracy- The key for success

It is one thing to develop products and bring them to the market but another to provide superior quality in a standardized serial production that you can count on. Quality assurance comes first priority at epmodex!

We continually develop and optimize our business organization to rest assured that you can fully rely on our quality- today, tomorrow and in the future.

We measure precision

One of our key steps is the precise measurement in all sectors and models. In order to avoid even the smallest errors we use high-end measuring equipment and- methods for dimension control (e.g. 3D- Measurement Machines CMM, CT-Scanners, etc.) conducted by our carefully selected qualified operators.

Test equipment management - It's no coincidence

Properly functioning testing equipment for quality monitoring is essential, as this is the basis of any quality assurance.

The ISO 13485 framework for the manufacture of medical technology products obliges our customers to apply CAPA measures (Corrective and Preventive Actions), to guarantee traceability and change control throughout, to implement risk management that conforms to standards, and to make consistent use of training and document management. In order to meet these numerous requirements, a management system is needed that guarantees complete documentation and comprehensive monitoring and enables rapid, cross-departmental responses to changes of all kinds.

For this purpose, we use a powerful software in production that supports the management of test equipment, test equipment capability studies and the calibration of test equipment. From simple calipers to the most complex, multidimensional measuring equipment, from dial gauges to specialized and process-integrated in-house developments. We thus guarantee for an integrated test equipment management at the highest level.

We care just like: Trust is fine, control is essential!

WHAT CUSTOMERS SAY ABOUT US

CONTACT US

Consulting & Engineering

Hochbordstrasse 9

8600 Dübendorf

Switzerland

+41 (0) 44 200 11 00

info@epmodex.com

www.epmodex.com